|

What Is The Problem With Most Knives?

I believe that the problem with most knives can be summed up with the answer;

"Bad Design".

I believe that most knives suffer from a very bad design that renders them awkward if not painful to use in the field.

(although pretty to look at),

I have felt that the reason so many knives have such poor design aspects was due to many knife designers never having sought out the advice of us hunters and working men as to what we need in a reliable blade.

| The Targhorn |

|

| 52100 Steel Blade, 12oz Leather Sheath |

The reason the DaQotah Targhorn looks the way it does, is that I have attempted to place all my knowledge of a lifetime spent using blades into the design of one truly exceptional knife.

The Targhorn reflects my experiences with knives that have failed me in the field. I sought to bring into one package, all the understanding I have gained about the nature of a true High Performance Blade

The Targhorn is not a pretty knife, it will never win an award for looking clever or sexy, nor does it even stand out in a crowd next to other hunting knives.

But deep down within her soul her beauty is reveled in the simplicity of her design. She is a knife that works with the hand, not against it. She is strong, yet easy to hold. She has a design that is in harmony with the curves of the human hand, she flows with the movements of that hand as if she were just a natural extension of the hand.

To learn the reasons behind each element and decision that went into the design of the Targhorn, its necessary to first study the flaws that appear in contemporary knives that we all grew up with, and struggled to use.

We are going to examine some basic camp knives that I still own, that I got as gifts from older hunters when I was younger, and remained with me on camping and hunting trips all over this county.

| Below ,knives we will compare to the Targhorn |

|

| The 1970s Knives |

The knives we will be comparing to the Targhorn are just a common outdoors knives sold in sports stores in the 1970s.

But they have many of the design problems that are also common to knives sold still today.

As you read along, and study the photos, notice how a problem of my 1970s knife has been corrected in the Targhorn.

This discussion is broken up in to three sections. We will deal first with Blade design, comparing common hunting knives to the design of the Targhorn.

We next will discuss the handle design of the Targhorn and what went into its design.

And we will end this discussion with an examination of the sheaths. This is widely overlooked by most knife buyers, yet is responsible for most knife losses.

Comparing the blades.

We will begin at the point of the knives, and work our way back.

The Point

My 1970s knife is designed to resemble the Bowie knife. It retains the distinctive Clip Point of the famous Bowie knife that is well known to us from the TV and the movies.

The trouble with the clip point is that its both hard to sharpen and hard to use. The clip point is very weak at the tip, and when you do try to sharpen it on a stone, there is a good chance that you will round the point off. I cant tell you the number of old Bowie knives I have seen at swap meets that show this type of rounded off tip.

When you actually try to choke up on a knife with a clip point,

you will notice that the point seems behind your finger,

this leads to an out of line feeling as you try to make delicate cuts,

the point seems out of balance with the fingers that are trying to guide it.

Now notice the point on the Targhorn.

The point is called a dropped Point, this means that the point drops below the upper line of the spine. This places the tip of the blade more centered to the blade of the knife.

When you choke-up on the Targhorn, the finger/Blade point aliment seems more balanced and lined up. The fingers seem to point right to the tip doing the cutting, the movements of the guiding fingers seems to flow down to the point of the knife.

The Spine.

The spine of the 70s knife is too thin to press down on without pressing painfully into the finger. Notice how the thin steel seems to want to dig into my finger.

In another example of a design flaw that many knife carry is the introduction of extras to the spine of this knife.

This knife has saw teeth along the back of the spine.

I guess having an option of a saw in the field is what I must have been thinking when I got this knife. However in real life, this made a very poor saw. In 15 -20 years of use, I cant think of even one time where I was able to use the saw teeth as I expected.

Whats worse, the shear placement of the sharp saw teeth actually cased more harm than good. Many times I wanted to place my thumb onto the spine to apply more downward force on the blade, only having to back off due to my fingers being cut into by the saw teeth.

Another thing that is seen on many hunting knives sold today is something called a Gut Hook. I also believe that the gut hook is a bad idea that must have looked good on paper.

But I can tell you stories of the many more times a gut hook got in my way, then proved useful.

Did you know that the Gut Hook was actually invented by a guy to help him lift coffee pots out of a hot campfire without getting burned? Its true, and from this small change to his blade, the whole idea of trying to combine two tools (The gut hook and the knife) was dreamed up

I just think that if you need a tool, then go get the correct tool for the job.

The gut hook might be something needed in a few cases, but for most of us users the gut hook only looks cool. In real life they prove to be more trouble that they are worth to us.

The spine of the Targhorn is wide; the edges are rounded to be soft on the fingers. Pressing with all your weight on the spine is easier on the fingers due to more surface area on the spine to distribute the weight.

The Sharpened edge.

The sharpen edge of the 70s knife is what they call a flat grind. The blade has a very pointed bevel that ends in a very sharp point. Flat grind knives are among the most popular knives sold today. They are found in all knife store displays, most likely you own a few knives with flat grind bevels.

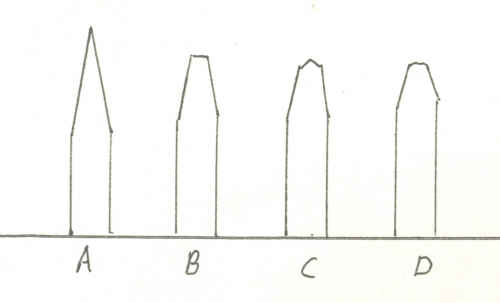

| A=new blade B=dull flat grind blade |

|

| C=sharpened flat grind D=dull again |

The trouble I have with the Flat Grind bevel is that although they are taken home from the store extremely sharp, once used and then sharpened by the owner, they tend to get duller fast. After each time the owner sharpens them they seem to get duller faster and need to be re sharpened again. as time goes on, the owner will likely get very frustrated that his expensive knife just does not seem to get sharp and stay sharp as it was in the store.

The problem is that we only are sharpening the very last part of the flat grind bevel. As the blade wears down and we keep sharpening it, we are actually digging deeper and deeper into the ever widening flat grind. So our finished sharpened edge actually does becomes flatter and flatter over time.

With just a little wear, the edge becomes dull again, and so the endless cycle of sharpening the blade goes on.

The edge of the Targhorn is a Convex edge. The curve of the blade starts way up near the back of the spine and flows all the way down to the cutting edge.

Only the convex grind offers the blade the mass of steel needed to support the cutting edge.

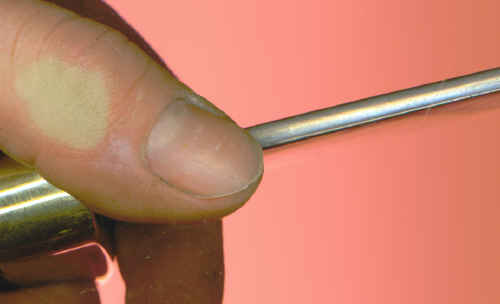

The way we sharpen the convex edge is a little different that the common way we sharpen the Flat grind knife. Instead of just sharpening the cutting edge with a stone, ( you still can use a stone but there are other easyer ways), we can use a mouse pad and wet/dry sandpaper. Just slide the flat of the knife blade across the paper that has been placed on a mouse pad. ( see photo)

As you slide back the knife to yourself sharp edge pointed away, you just slowly lift up the spine of the blade until you hear the sharp edge start to scratch the sand paper, then repeat the other side.

This is called stropping the blade, and results in a razor sharp cutting edge. The use of sandpaper method of sharpening the convex edge also means that we are not just removing steel from near the edge. (and thereby blunting the knife as we saw happening with the Flat grind). As we use the sandpaper we are removing steel on the whole side of the knife at the same time.

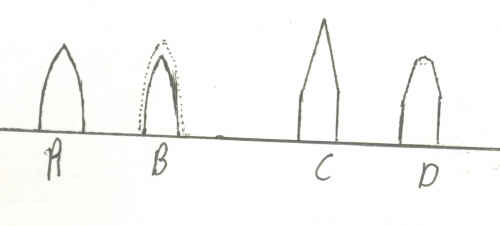

| A=new convex blade..B=after sharpening still cuts |

|

| C=New flat grind..D after sharpening more flat point |

The Targhorn retains the same blade design and edge supporting characteristics throughout its lifetime.

The Choil

The Choil is the cutout that appears on most all hunting knives.

This one thing is the most trouble to us knife users that any other aspect of knife design. The choil tends to snag whatever you are trying to cut. Try to plunge a knife with a deep choil into cardboard and then pull it out; its hard to do. The choil snags the cardboard, making any sawing motion that could be useful in such cutting all but impossible.

The choil dates back into history. The reasons for its appearance long ago are do to the forging process when the steel of the knife blank was hammered, spreading the steel out as it was thinned for a blade. But on a using knife for todays workingman, the choil is obsolete.

There is no Choil on the Targhorn. Notice how the material that you would be able to cut with the Targhorn would flow right onto the cutting areas with nothing to interrupt them or snag them.

This lack of a choil also gives a needed place for a finger to rest when you need to choke up on the blade for delicate cutting.

The Ricasso

The Ricasso on most knives is just an after thought. Something left over from the grinding. There is no room for the fingers to rest with comfort or safety.

The Ricasso on the Targhorn is always at least ¾ of an inch long. This amount of length provides plenty of flat area for a finger to rest as the knife is used. A knife with a wide Ricasso area is superior to knives that lack them; there is no question that all working knives should have adequate Ricasso.

The Guard.

The guards on my 70s knives are too thin to be any good. The purpose of a guard is to protect the hand. But the guards seen here are so thin that they themselves could cut into the hand. There is nothing rounded in their construction, nothing ergonomic.

Being so terrible thin, it is very possible that if you were hammering down the knife,( as if you were chopping into thick ice in the cold winter), that your hand could actually bend the guard flat. A bent guard would then be not protecting your hand from sliding onto the sharp blade of your knife. Remember, many times you may need to use your knife under extreme conditions, working in poor light, with frozen fingers, you got to be able to trust that your guard is going to protect your hand no matter if you can see what you are doing or not.

Examine now the guard on the Targhorn.

Yes, its HUGE!

Built to take a beating and keep going. There is nothing here that is untested, nothing flimsy. The guard is made out of a solid peace of ¾ inch brass. This is a pierced Guard design, meaning that the brass of the guard surrounds the tang of the knife. The curve of the finger cutout on the guard of the Targhorn works to keep the fingers in the right position. When you choke up on the blade with different grips, you have the guard to lock between your fingers. This ability to use the guard from both sides gives a powerful stability to the grip.

The Handle

The handle on most knives was designed to sell. They are made to look good in the showcase. they are very symmetrical.

But is your hand?

. Take a look at your hand one time. Notice and perfectly round parts? Nope?

The human hand is a collection of angels and gentle curves, nothing symmetrical at all. Then why is a handle that is designed for the human hand not built to conform to the shape and movement of that hand?

The handle on this knife is perfectly round.

This seems correct at first glance, but ever hold something hard that is perfectly round and work with that tool a while?

Think of a broom or a rake for instance.

They have nice round handles too, just like this knife, however with just a hour or so of average use, my hand soon starts to develop blisters as the hand is forced to conform to the handle.

The handle on the Targhorn is ergonomic. Its created to work with that hand during the cutting chores. The handle has two curves in its lower part; the curves mimic the natural way a hand works when we squeeze down on something. The 2nd curve also allows the fingers to the rear of the handle to help hold the knife secure. Too many knives are lost due to the way many knives ask all the work to be done by the very first finger alone. The Targhorn spreads the work to the rest of the hand.

The curves also allow for an easy handhold to pull the blade from the sheath with one hand. Something very important during times of stress when seconds may count.

The aft end of the knife

The butt ends on many knives sold today have things like nuts twisted on or perhaps they have a ornamental design elements.

This is also a design flaw for a true working knife.

The end of the handle should also be rounded to allow the pounding of the blade into tougher materials.

Notice the rounded end found on the Targhorn. This is designed to allow the palm to pound on it with out hurting the hand.

The Sheath.

The sheath on my 70s knife has two snaps to help hold the blade in place. At first this seem superior to my Targhorn pouch designed sheath.

The snaps fool us to think that they will do the job to hold onto the blade; in real life the use of snaps and such types of retainers actually promotes the misplacing of knives.

The snaps have to be undone with two hands before the knife can be dawn, this also means that just to place the knife away for a moment as you work on a project means you have to stop, and then occupy both hands as you struggle with the snaps.

If you dont snap both snaps, the blade will fall out of the sheath.

What happens in real life is that people decide that it would be faster just to place the knife down for a moment then to have to stop and hassle with the snaps, only to have to again to unsnap the knife when you might need it.

Knives that get laid down rather than returned to their sheath, become lost knives. Thats how we lose them. They dont normally fall out while we are carrying them. We always seem use them and then notice an hour later when they are missing, and have to think back to that last time we used it.

The sheath of my 70s knife also has rivets that due to the fact that they dont give with the movement of the blade, have started to tear out.

The Targhorn has a pouch sheath.

It allows the user to reach for the knife without looking with one hand.

Also the knife can be safely placed back into its proper sheath with one hand as well. You dont have to stop and deal with snaps!

A knife in the sheath is never a lost knife.

The sheath is made of 12 oz saddle leather that is also used on may gun holsters.

This type of thicker grade leather resists tearing.

There are no rivets on the front of the sheath, everything is able to move and twist with the sheath without tearing out.

The Targhorn sheath fastens to the belt with a very wide belt loop. Such a wide belt loop helps distribute the weight of both knife and sheath and allows freedom of movement.

The belt loop is secured to the body of the sheath with 3 rivets. A sheath that does not make use of rivets to hold the belt loop to the sheath is more likely to fall apart due to the blade cutting the stitching

..and, thats why the Targhorn looks the way it does!

|