|

The Targhorn Sheath

There is an old Viking parable that is roughly translated as:

"No Blade is worth spit if a warrior is unable to lay his hands on it when he needs it."

The Newest of DaQo'tah blade has been mated to a most excellently designed sheath system.

The Sheath of the Targhorn is more of a holster design than a traditional knife sheath. The ease that the knife can be drawn is reminiscent of a fast draw weapon of the old west.

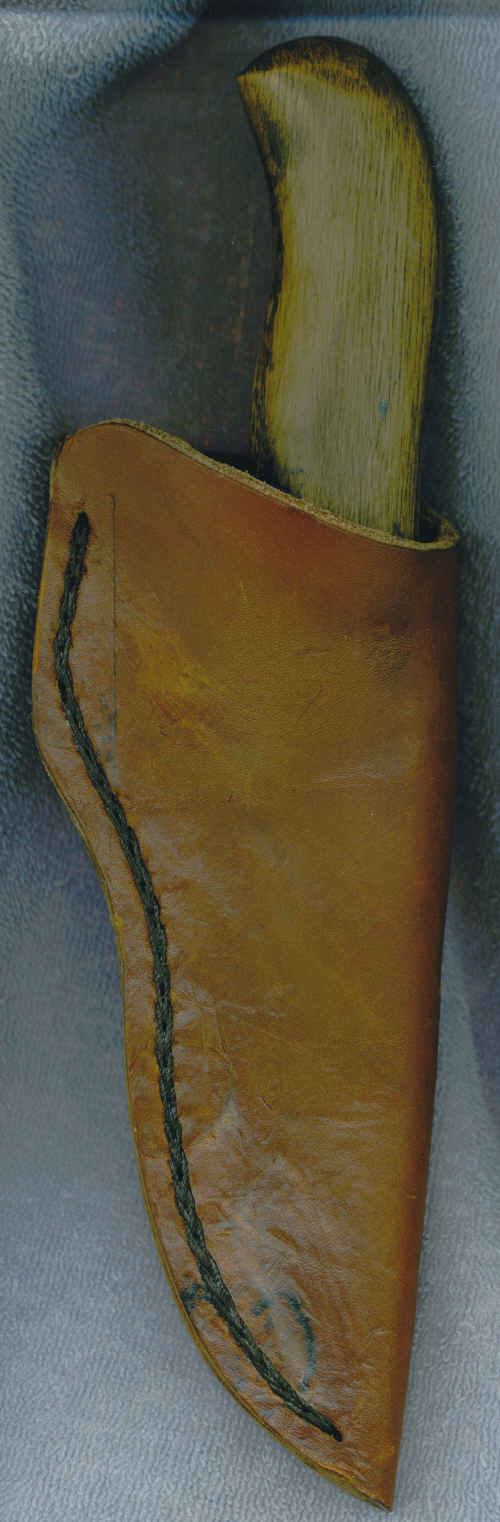

The following photos will document the different aspects of the Targhorn sheath.

The Cut of the leather

Here we see the Targhorn tucked safely into its sheath, the guard of the knife extends down into the formed leather about 1 and ½ to 2 inches.

The leather is curved down at the opening of the sheath to allow for a more fluid, one-handed return of the blade to the sheath after each use.

The shape of the Targhorn, with its slight bulging hook at the end of the handle forms a very natural pull position for the hand to grasp with out looking.

This handle allows the Targhorn to slide out of the sheath effortlessly, bringing the blade to bare quickly and quietly, (very important when seconds might count)

The Targhorn sheath is made out of heavy 12 oz leather that has been formed around the body of the blade and handle, the sheath is also submerged in a hot bath of Mink oil and hot wax. The leather soaks in this mixture of oil and wax, and the resulting finish to the leather is both water resistant and surprisingly strong.

No Front Rivets

The Targhorn sheath does not have a rivet at the opening of sheath, as do most knife sheaths. The reason for this is that this rivet tends to tear out and leave a unsightly hole. The reason the rivets in this area tend to fail is that the leather wants to naturally give with use, there is much bending and scrunching over the life of a knife sheath.

All the materials used to construct the Targhorn sheath must take this type of movement into account.

Rivets that are placed into the top of the stitching area, will resist this bending, and eventually will tear out.

Hand Stitching

Notice the hand stitching.

Each Targhorn sheath is stitched by hand, this is unlike most knife sheaths seen on the markets today. This stitching pattern is very strong, and also quite beautiful in its complexities.

The Gusset

In order to keep the blade of the Targhorn from cutting the stitching when the blade rests in the sheath, a separate gusset of thick leather is stitched into place.

The design of this gusset also allows a place for the Brass guard of the Targhorn to rest on top of. This keeps the sharp edge of the blade away from the stitching.

By keeping the blade suspended in the sheath, the blade also keeps from becoming dull due to rubbing on the leather.

Any knife that does not rest in a sheath away from the leather bottom, is a dull knife.

The Belt Loop.

The Targhorn sheath has a very large and accommodating belt loop.

This is designed not only for the wide belts of hunters and construction workers, but it also allows more comfort while being warn with more traditional dress.

The over sized belt loop allows the sheath to be pushed up and out of the way while sitting in a vehicle.

The belt can slide the sheath up, and then later the belt can slide the sheath back to normal positions.

The Rivets

Here we see the correct placement of rivets on a knife sheath.

The 3 rivets work to hold the belt loop fast to the body of the sheath.

Too many knives that have only a few stitches and glue to do the work of binding the sheath to the belt soon fail when the Knife cuts the loop stitches when its being taken out or replaced.

Rivets dont fail,,,

The Targhorn and Targhorn Sheath.

The proper sheath, allows a knife to be drawn with one hand.

The Targhorn sheath has no snaps that could stick or freeze up in the winter.

There is no Velcro to wear out, and need to be replaced.

This sheath is the end result of many years of testing and evolutions.

The Targhorn indeed has been mated to a most excellent sheath, and together that make a very attractive and functional combination.

Blade is of 52100 steel ,coal forged

Handle is of oak and brass

Sheath is of 12 oz leather

|